Modifying an LIM can be done for a few different reasons. Better air flow, better coolant flow, keep an L36 from hyrolocking etc etc.

Cleaning the LIM:

I have found that working on anything car related is easier when clean. Take a moment and clean the parts. Typically I'll use Simple Green or Purple Power to degrease an item. However when it's available a pressure washer makes quick work of cleaning and gives you a bath at the same time. After drilling/tapping and grinding on your manifold, you should rinse it with water and air dry. This will keep anything out of the rest of your motor and cooling system. It is assumed your manifold is off for all the below items.

Coolant passage blocking:

There is a small loop in the coolant system that brings coolant up out of the LIM into the UIM or SC and into the throttle body. This loop is considered by most to be pretty worthless. It may have a purpose in below freezing temps where a throttle body might ice up. In all the research I've done, it's only been found to potentially be a problem at the north and south poles. The heat reduction to a TB by doing this is minimal, if even measureable. This is commonly done for Gen V swaps to stop the flow before hitting the throttle body adapter. Also in NA cars to keep coolant out of the plastic manifold that can rupture and fill the cylinders with coolant.

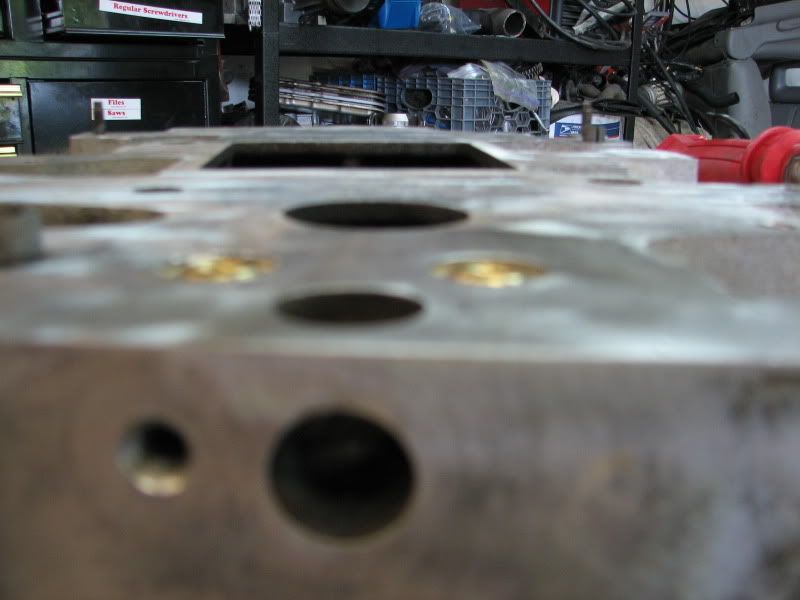

Here is an L67 LIM. See the two recessed holes. Those are the ports we are speaking about. On NA manifolds and many L32 manifolds those are not recessed.

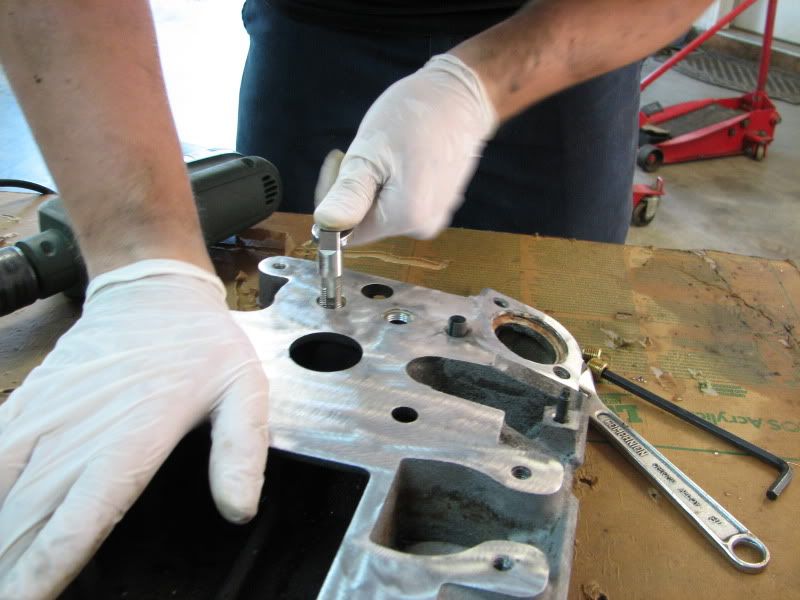

You drill with the proper drill, then tap with 1/4" NPT tap.

Using a little pipe sealant you insert the headless 1/4" NPT pipe plug. Tap it slowly and keep trying the plug. Being NPT, the threads are tapered, you don't want to tap too far and have a loose plug.

Increasing Coolant Flow:

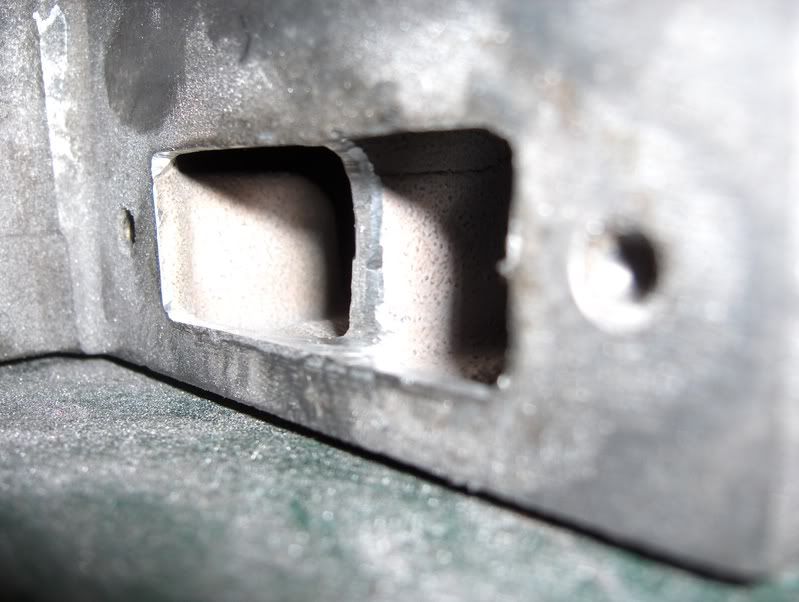

Now if you have done the above and blocked the TB coolant ports, your coolant flow is reduced slightly. In our 3800 motors, it is known that cylinders 3 and 4 (both middle cylinders) run hotter than the other four because they are in the middle of the heat sandwich. I like to increase the flow from the rear head to the front head (thermostat area) by opening up the area behind the endcap on the LIM. This cap is under the throttle body. Have a dealer only rear intake coolant cover gasket (24505049) on hand and remove the two 8mm bolts holding the cap to the manifold.

I find that hogging it out a bit to look like this helps keep heat from building in the rear head.

Before:

After:

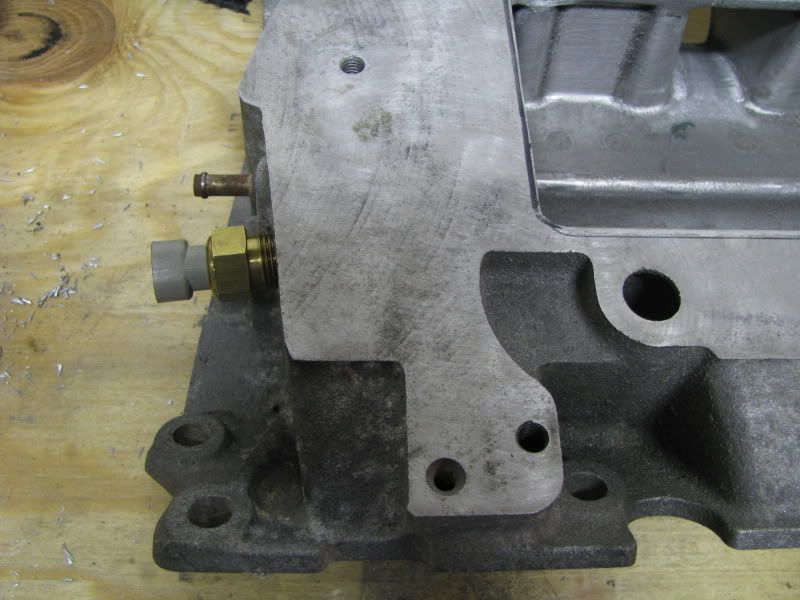

Post SC air temp sensor:

If you have an interest in an air temp sensor, the best sensor appears to be an early 90's 350 TBI air temp LIM sensor. Looks like this

They appear to be 3/8" NPT and the best placement appears to be in the end of the LIM near the #1 runner.

Porting the runners:

This should only be done if head porting work has been done. Otherwise if you gasket match the LIM runner and not the head, the air hits the edge of the head and that causes a disruption to the air flow.

I use an old gasket and bolt it to the LIM, then using a carbide bit, open the port to the gasket size, and smooth the rest of the runner from there. Sorry, no pics.

Opening up the inlet:

If you are going from a Gen 3 to a Gen V or intercooling, you will want to open up the LIM's air inlet. This is really dependent on the size/shape of what you are adding.

Easy