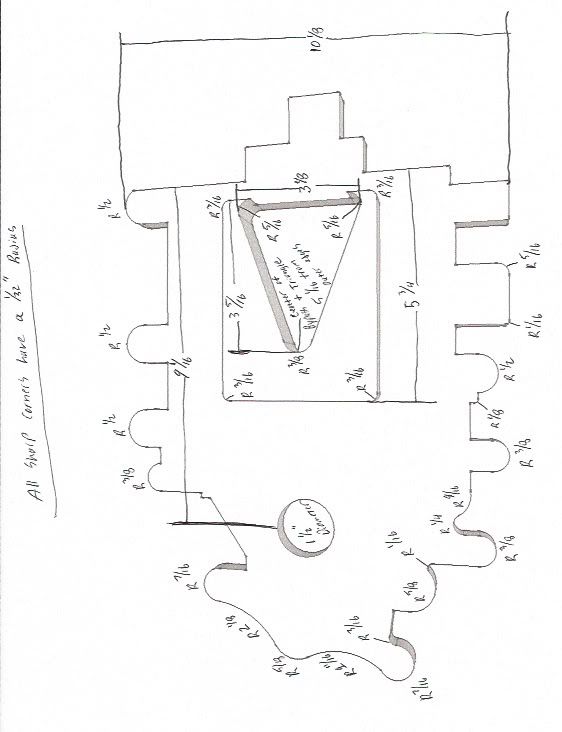

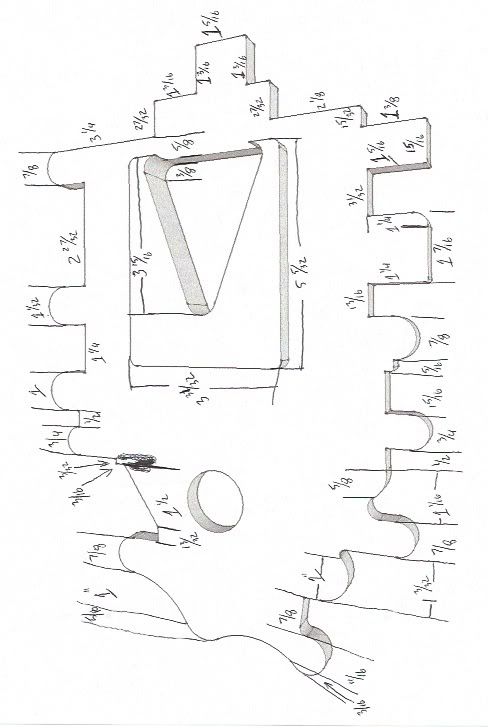

I do not have experience with the real CAD programs that CNC machines work with but I am pretty good with Sketchup. I did a to scale (as best I could) drawing of the mounting surface of the M90 and I was wondering if anyone knew how to turn that into a file that a cnc machine could read?

Background on what I am trying to accomplish...

I have a 240sx KA24DE engine that I am going to remote mount the M90 onto the exhaust side of the engine. I want to cnc a flange that will bolt up to the bottom of the M90 (minus all the coolant holes) and extend into the supercharger just enough to seal off the silencer holes and only leave the triangle outlet for an opening. I was then going to modify a 3" pipe to weld directly onto the triangle outlet and drill in a tee for the 1 1/2" bypass line to go back into the charger.

I have attached a screenshot of the Sketchup File but if someone knows how to transfer it to CNC code then I can e-mail the file to them.

Thanks for the help,

Zac

Fellow 240 owners are getting 250hp 250tq out of the M62 so I am hoping to get around 325/325 out of this setup.

Fellow 240 owners are getting 250hp 250tq out of the M62 so I am hoping to get around 325/325 out of this setup.