Hi everyone

It's some time ago that i ask some questions regarding a engine rebuild form people that now were they are talking about (this is the place)

And now that i finely got the stuff i orderd from ZZP like.

1xRollmaster timing set Model: Double

1xValve Seals Option 1:Set of 12

1xEngine gasket kit Engine:L67 Option 1:add Felpro head gaskets

1xValve Spring Retainers Model:Modified steel

1xFront cover gasket Model:standard paper

1xThermostats Model:180

1xClevite 77 Bearings Option 1:Main bearings (standard)

1xClevite 77 Bearings Option 1:Rod bearings (standard)

1xPiston rings Size:standard bore rings

1xCrow Cams valve springs Model:130 lb CrowSprings

1xX-P HOT Cam

1xARP Head Studs for the 3800 Option 1:standard 6 point nuts 193-4001

1xSupercharger Coupler

1xEaton Rebuild Parts Model:M90 Option 1:Seal + snout and needle bearings

1xZZP Modular Pulley System Size:3.0 Color:Clear

1xHydraulic Roller Lifters By Competition Cams Model:OE-R 875

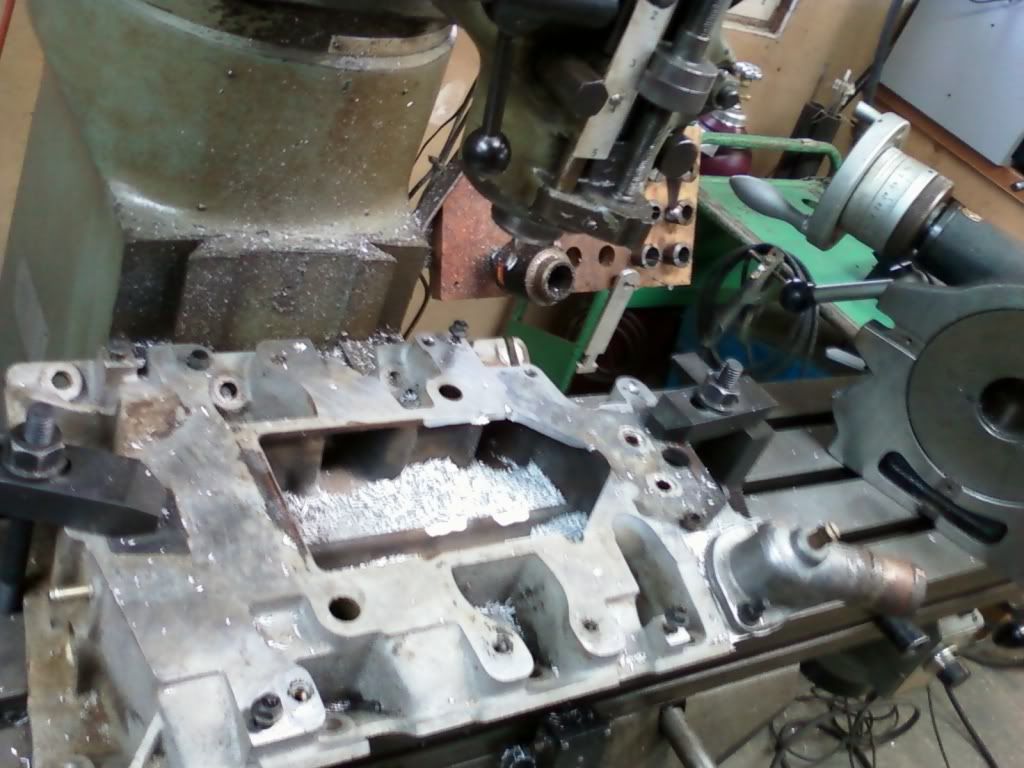

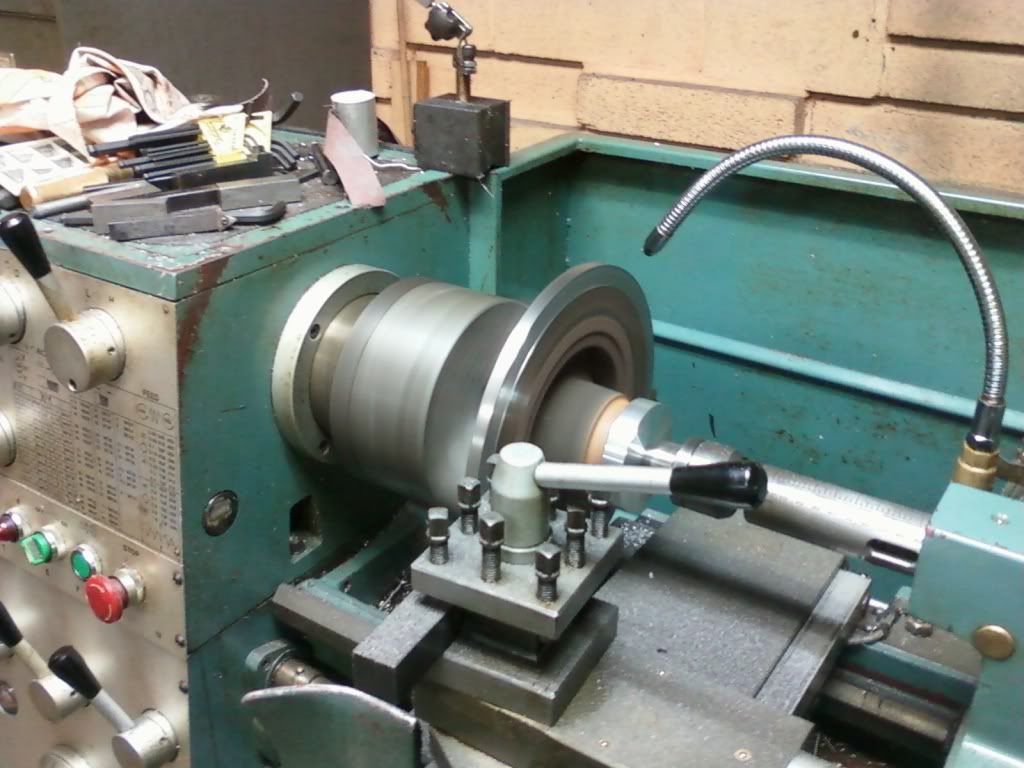

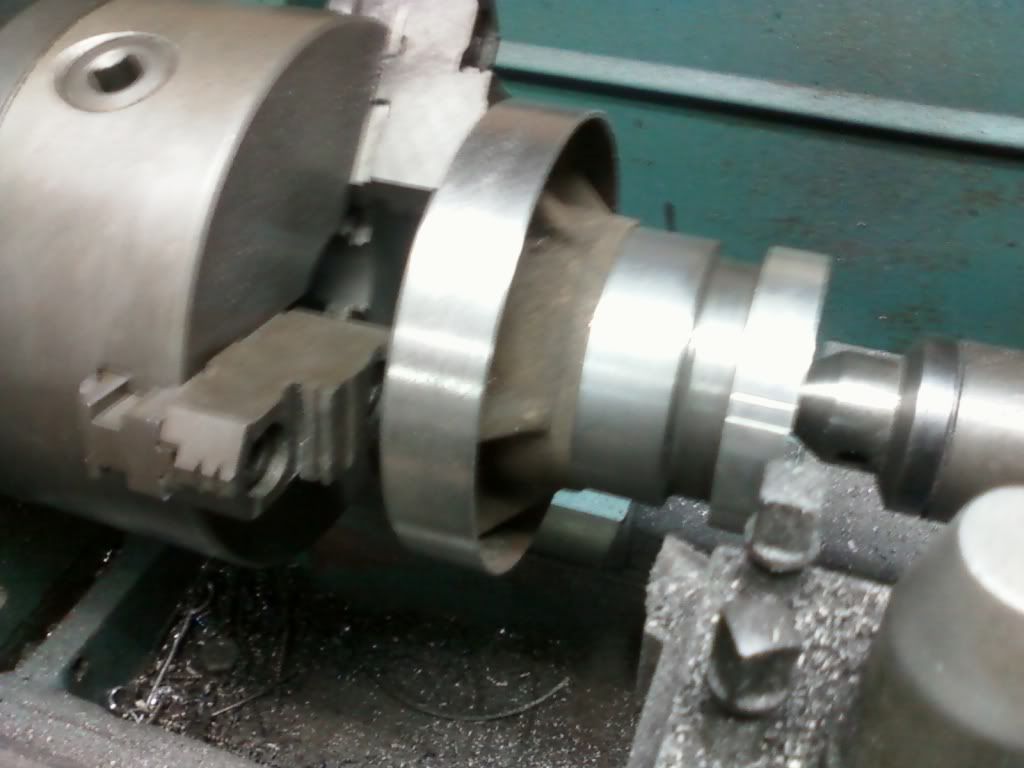

I send my blok to a shop to check and if needed do boring/honing on the cylinders.Got the engine 1 week later back and it looked real nice.

now i started to rebuild the engine and find out that the most bolts are Torque to yield ,and can't use the old bolts

What is the best way to. Do i need to use new stock replace bolts or

Order the arp main studs bolts with the arp connecting rod bolts

The thing is on the site of ZZP there is a text quote Block line boring is recommended after the install of main studs / Machine shop work on the rods is required when changing the rod bolts to avoid spinning a bearing