The shifter install is pretty straight forward, the front bolt goes in the factory location. For the rear, you use the auto shifters bracket, and enlarge two of the holes.( the slots by the black bolts)Perfect height.

Now the fun part of the shifter install, the cables. This is were i screwed up at first, i found a factory half knocked out hole in the firewall (engine bay side) and thought "huh, must be a carry over from the first gen w bodys, this must be the factory cable spot. Damn im lucky!" Well... it wasnt, i was an inch too short of my cables reaching once the drivetrain was in. Soo this actually got moved farther right after this pic.

This interior hole got moved slightly as well.

And all together shifter wise.

Now with carpet

And interior installed ( This is actually out of sequence, once it was done and driving, but before i shortened the shifter 2 inches.) The oil pressure gauge is temporary.

After i shortened the shifter a little.

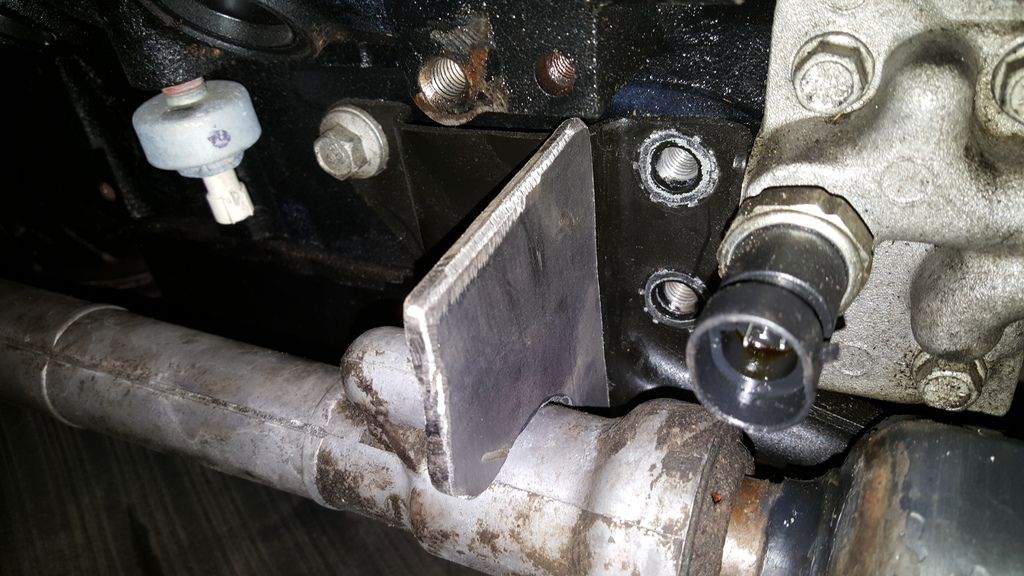

So next up, was the drivetrain side of things. The first task was securing the driverside axle tube to the engine. Now, instead of using an aluminum oil pan from an 05+ , i just decided to make my own bracket. Mainly because it needed to perform oil filter duty as well. This is a flat plate of steel that is in a c cupping the axle tube for mock up.

what it looked like before welding

Then i put a small piece of 90 degree angle behind it with holes i pre drilled to line up with the motor mount bar bolts. Tightened everything down, ready for tack welds.

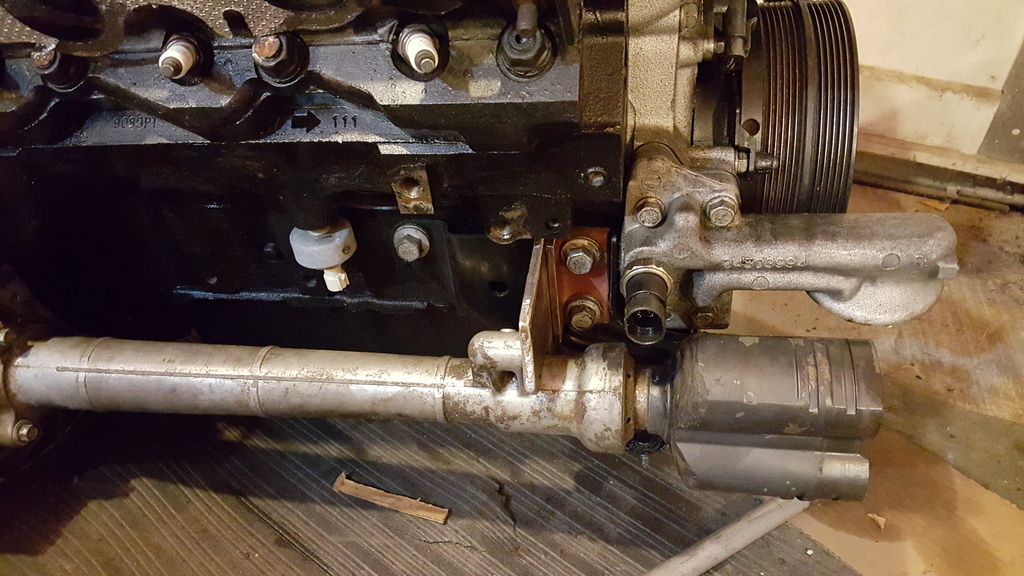

Got it tacked, and ready for welding.

Got it welded, only did the backside, still had to mock the other plate getting welded onto it for my oil filter bracket.

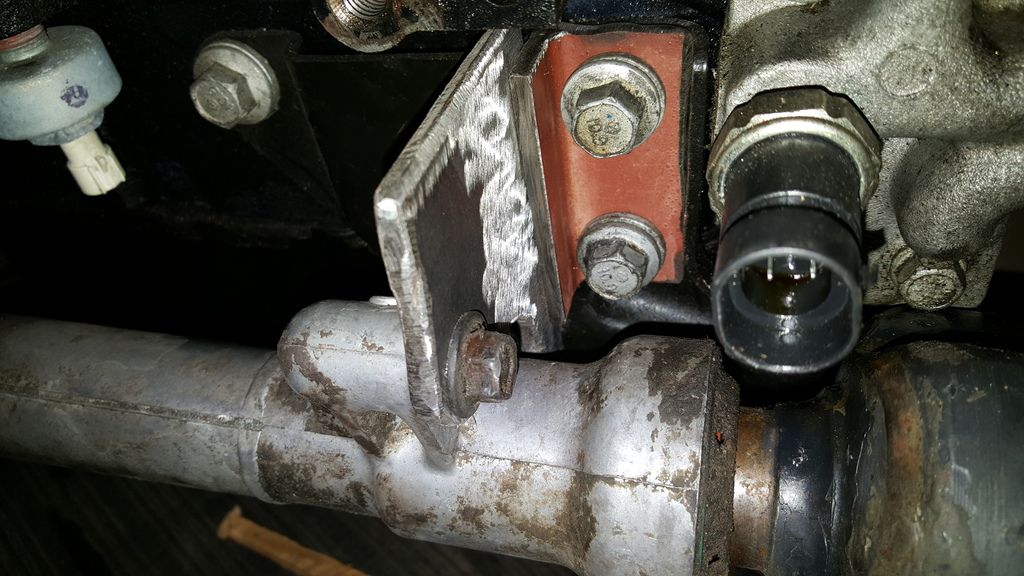

My oil filter bracket

The other side of it. Better weld on this side, not that that 1 pound oil filter needs alot of support. lol This project was my first time welding.

And all done

Here is the bracket temporarily installed before the tranny gets cleaned and painted.

Next, i power washed the tranny and painted it. Ended up painting the selector black before i was all done. Notice that big ass piece of bellhousing that has been welded back on? I noticed it after i got all of the caked on crap off of it. My guess is that someone tried tightening this thing back up after a clutch job and didnt quite get the alignment dowl in the hole. lol. At least they seemed to have welded it up true. So i got that goin for me, which is nice.

another angle

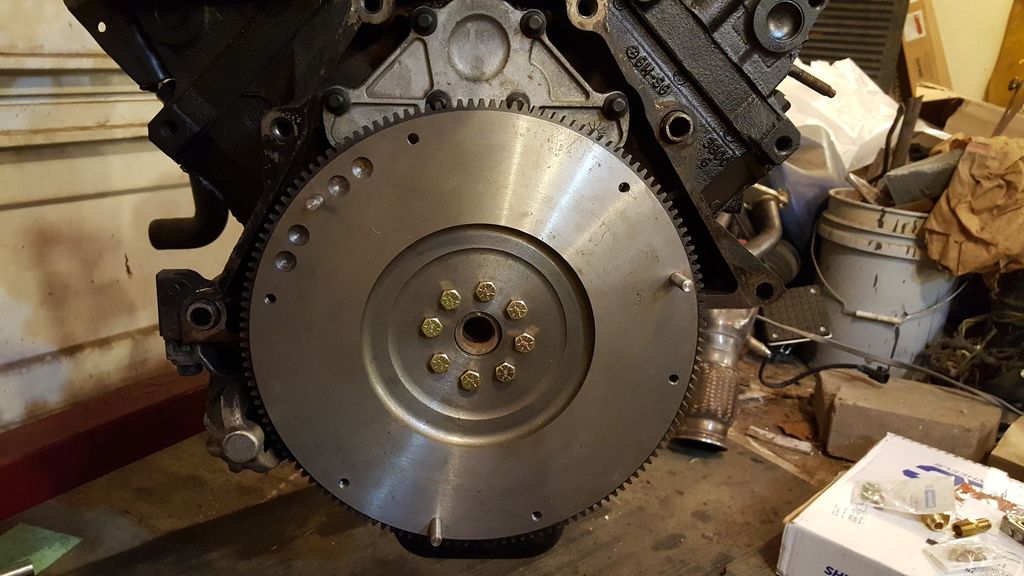

So next, i got my flywheel and clutch mounted. This is a machined down 3800 camaro flywheel, and it has been mirror balanced to my L67 flexplate.( those alighnment pins that are in there in the pic gotta come out).

I really cant remember if this is a stage 2 spec clutch or stage 2+, whatever the 400ftlb one is. Smooth engagement, no chatter, have had no issues with it. I chose this one, because the fiero guys start cracking the cases on these shortly after the 450ish mark. Figured clutch slip would be a good indicator to stop adding power instead of the tranny case giving up.

With how well this project has been driving so far, i may intercool and really see how much $hit this 282 will take, or go untill i get clutch slip. Which on a blower setup would be pretty far for 400ftlbs at the flywheel.

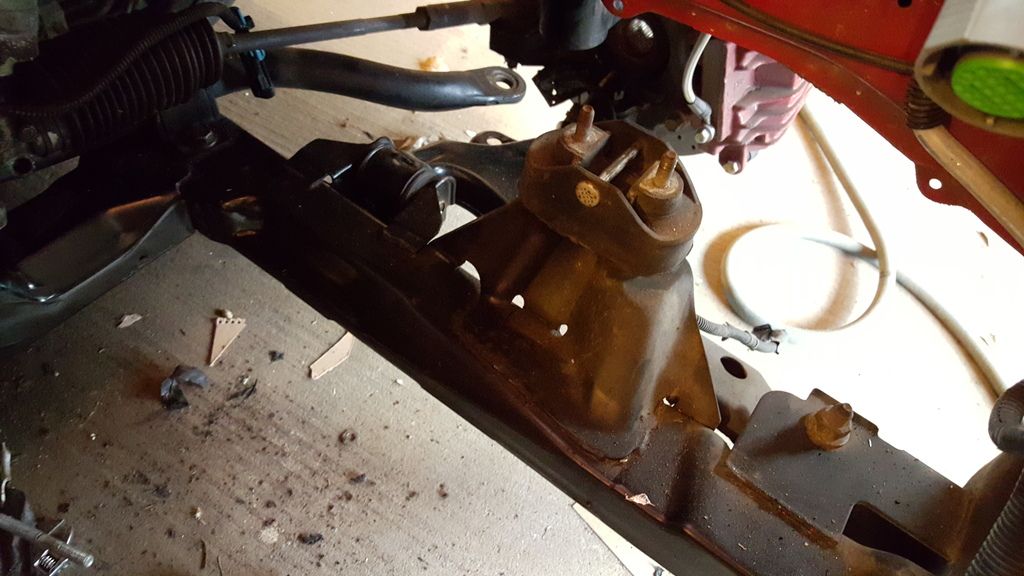

Next, this auto tranny mount needs to go.

aaand gone, never existed.Theres two holes under there already factory pressed for the manual on the bottom of the chanel. I will put picks of them someday.

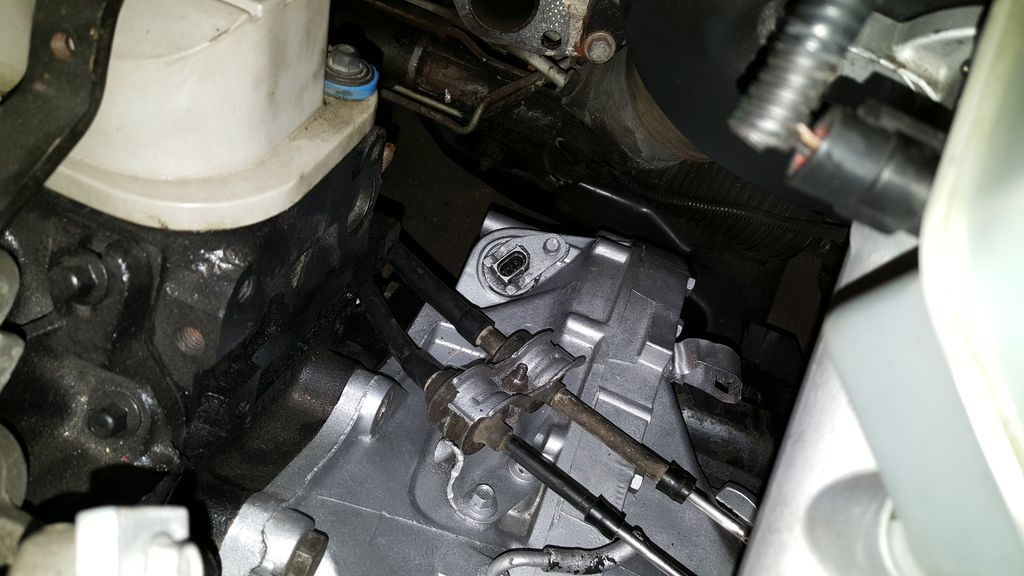

Here she is in the car with the cables hooked up (after the whole cables in the wrong spot thing i mentioned earlier) And this is without the new vent tube and reverse lights hooked.

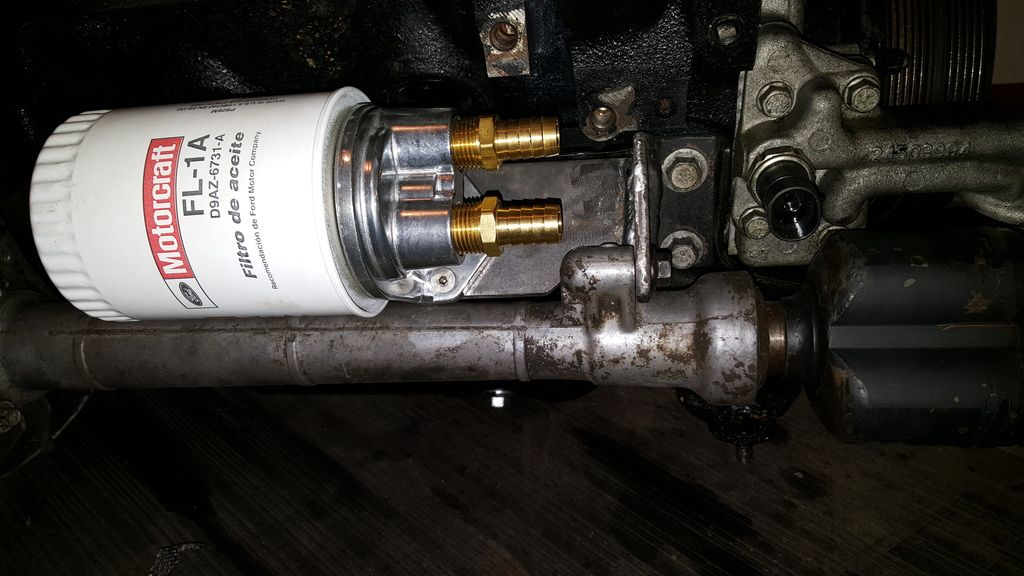

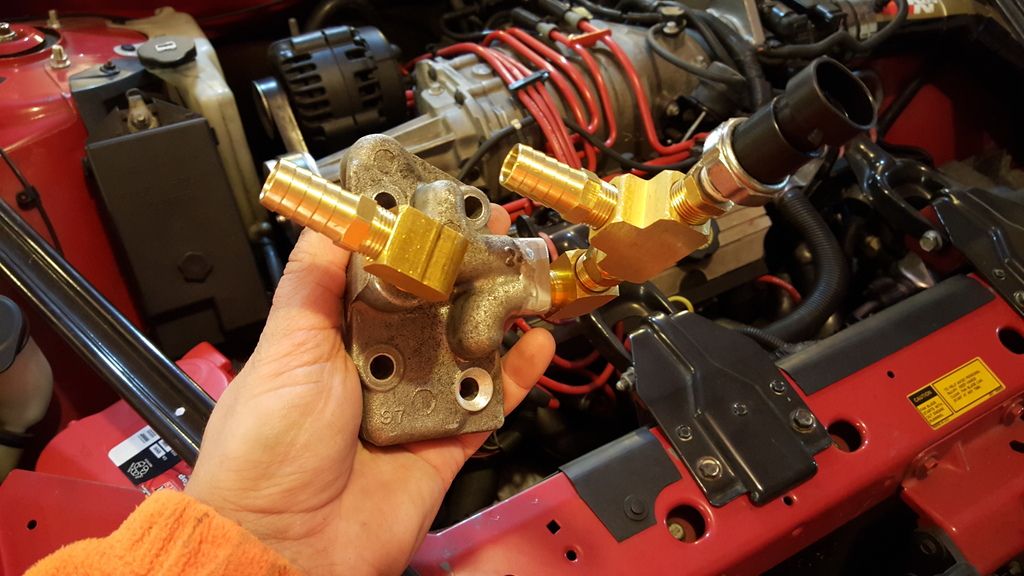

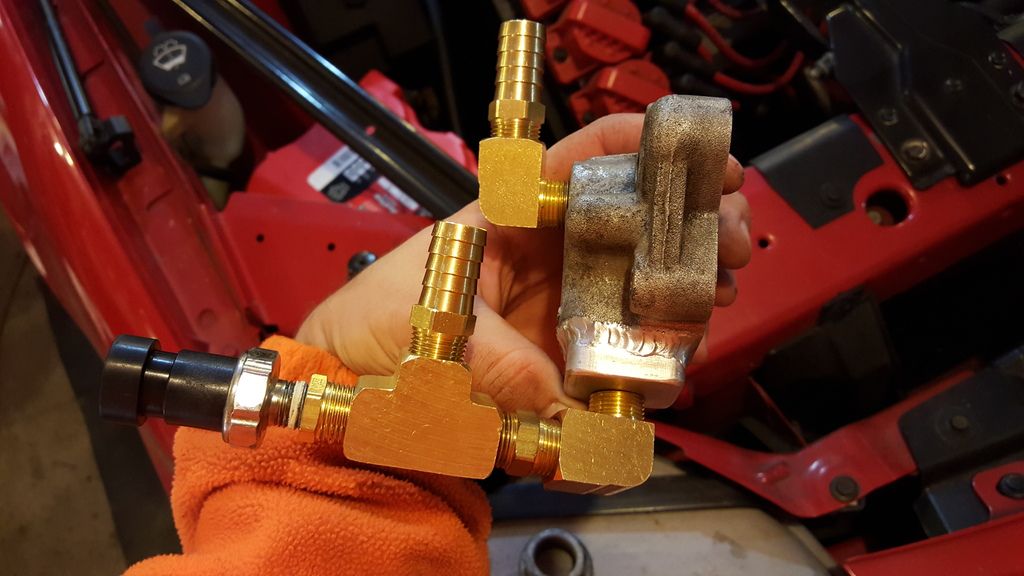

So, the last thing i actually installed, was the oil filter and adapter setup. I did this once it was in the car. Now, from what ive seen, everyone who does a getrag swap uses a buick reatta oil filter adapter with a filter relocation and goes about there lives. I looked, and looked and fukin looked, couldnt find one used or buy it new from gm. For those who are wondering, the factory oil filter adapter does not clear the cv axel, wont work in factory form. So instead, i modified the factory adapter to work. I tweaked the brass fittings a little after these pics, but you get the point.

So that is the neck cut off, a block of aluminum internally welded in the top port of the neck, then an aluminum block which you can see welded and tapped. I drilled and tapped the oil sender hole bigger for the other fitting, and the lowest bolt hole was recessed, and a tapered allen bolt was used to clear the cv axel with extra room.

Another angle

This setup has worked out great so far, no leaks. But i am still looking for a reatta oil filter adapter, anyone reading this that has one give me a shout. Id gladly buy it off of you. I would still rather have a factory gm adapter on there, it would look so much cleaner.

So that was that, after i got that installed i started it, did some checks. Once everything was checked and rechecked, i drove to the gas station in it. That was a fun, but nerve racking drive, thinking of all the things i could have forgotten or left loose.lol.

Its an odd experience driving a car for years as an auto, then taking your first drive as a manual. Before i was done, i expected it might feel wierd or awkward. The only wierd thing about it was that it didnt feel wierd, it felt as if it was supposed to have a manual option, it just feels right. As far as the characteristics of the setup, when your doing 70 miles an hour, your right at 2500 rpm. This swap does not affect your speedometer, im still 1 mph higher than the gps speed and i havent changed anything. First gear is really short, you can take off in second if you wanted to. I find myself going from 3rd to 5th alot. When you poke it in 3rd to merge onto the highway, you just get done with third and throw it in 5th because 4th really isnt usefull just dailying it. On my setup, it will break traction in second and third, unless you get decent tires. With my potenzas, it holds a little better in third than with my cheaper yokohamas. In the end, this thing is just awesome to drive, especially when your in boost and you shift. The supercharger whine fluctuates up and down real quick when it loses traction in a shift then regains it.

As i said at the beginning, i will update this tread, and i will get a video up sometime soon. I will wait to put a video up untill my new hood and spoiler are on tho.

I dont live on here like some of you guys do, but if you have any questions, just ask or pm me. Thanks for lookin!