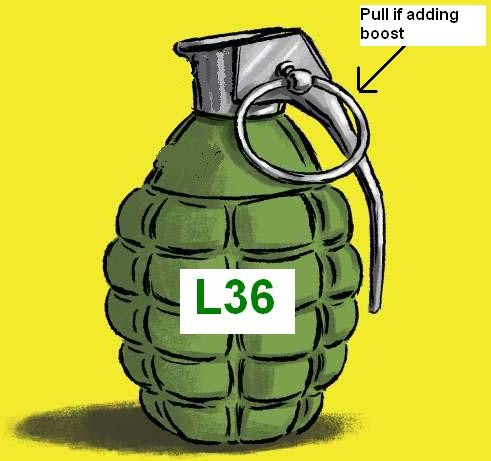

Thought you guys would get a kick out of that picture so I just had to post it. But it does tend to bring up heated debates.

I've been to college for this stuff, specifically hi-performance automotive. But beyond that, there's logic; and there's an understanding of what impact the bean-counters and emissions standards have on automotive design, materials usage, and build quality. Combine these factors and it's not hard to conclude that if an engine didn't come from the factory with boost, it probably won't be able to take much before buying the farm.

One very important thing I learned in college was there are two ways of doing things: the cheap way and the right way. I have seen a lot of people in the 3800 community try to do things the cheap way; but in the end they end up spending a lot more money just to be disappointed and would have saved money in the long run if they would have just done things the right way from the start. I'm sure trannyman can attest to this when it comes to people trying to put highly modded engines onto stock trannys.

Specifically what I'm talking about in this thread is the tendency of some people to want to put boost on their stock L36's. The L36 is a fine engine, but to put it bluntly, it just isn't designed for boost. Sure it shares the same block, crank, and same casting heads as its boost-friendly counterpart, the L67. But the L36 has much weaker connecting rods, pistons, and piston pins than the L67. These parts were simply designed to be as light (and cheap) as possible to meet emissions and get the job done (without boost). Having said that the stock L67's parts aren't perfect either. They are also a compromised design in order to meet emissions.

Emissions standards have forced auto manufacturers to make compromises for years when it comes to engine design. One of those compromises is in piston design; specifically sealing ring placement. On BOTH the L36 and the L67 piston, the ring package is very tight and located very close to the top of the piston. This helps keeps as much of the combustion gases above the piston (and not around its sides) as possible. But the drawback here is it exposes the top sealing ring to more heat. And when you throw in a very tight ring gap and tight piston-to-wall clearance to further improve emissions, you are left with a recipe for disaster if you try to add too much boost. Plus when you factor in the L36's already higher static compression ratio, you are really asking for trouble.

Basically the biggest factor at work here is cylinder pressure. Higher cylinder pressures = higher combustion heat. So it's not so much a factor of charge air temp; but more so it's the amount of air you are trying to pack into the cylinder. If the parts aren't designed or the clearances aren't set optimally for the application, then you are basically working with a ticking time bomb.

Now for my application I started with a L67 shortblock (engine w/o heads/intake) and had the cylinders honed to open up the clearance between the piston and cylinder; as well as open up that sealing ring end gap. I'm still using stock L67 pistons, and I've been able to put up to 15lbs of boost on them without failure. But I just don't feel comfortable pushing it any harder than that. Keeping my boost in check is probably what has allowed my engine to survive for the past 5 years.

Just some food for thought.

-ryan