First we'll get this out of the way. I'm not responsible if you screw something up, damage something, injure yourself/somebody else or anything of that sort.

I'm going to make a list of part numbers and such needed for this. I'll also go over what parts do what, since not everyone knows what specific pieces do, or are for. There's little things I'll go over that someone might not think of. I'm also going to cover a couple slight differences in front struts with this whole GR2/Excel G mess. When I can get some pics of assembly and what not, I will. I don't have much at the moment, but I need to dissassemble mine and put bump stops in, so at that time I'll show the assembly of them.

This is for 97-03 and 06+ cars. If you have an 04/05 you need to swap out your LCA's and sway bar for the 97-03/06+ versions.

One thing i'm not going to cover is front mounts. I don't know how, and I can't weld. I bought my front mounts already modified from "91PARKAVE" on here.

I'm also not going to get into setting up these cars for autocross using the correct spring rates, ride height, etc. This thread is simply how to make them, and slam the **** out of the car.

Spring rates will depend on how low you want. But 400# up front and 350# out back should be stiff enough for most people. After I get my bumpstops in, i'm winding the front coils all the way down so we'll see how it is. I went with QA1 since they're a well known brand and are reputable. But if you want to go with another brand they should work. QA1's aren't that expensive so that's what I chose.

Parts list

For the front this is what you're going to need, depending on the mount style. This is the style of mount I have.

On the bottom side of the mount, the "ring" that comes down is just small enough that a 2.5" ID spring will fit over it.

So for the front using that style mount here's what you need.

Springs (2): http://www.summitracing.com/parts/hal-12-400/overview/ These are the 400# springs. If you're really attempting to slam the hell out of the car you might want to go higher. But I don't have any complaints with my 400# springs.

Sleeves (2): http://shop.a1racing.com/cok12452-h.aspx Slides over the shock body and is what the adjuster nut sits on.

Adjuster Nuts (2): http://shop.a1racing.com/cok12460.aspx This piece is threaded and threads onto the sleeve. By turning the adjuster nut you move it up or down on the sleeve which lowers or raises the car.

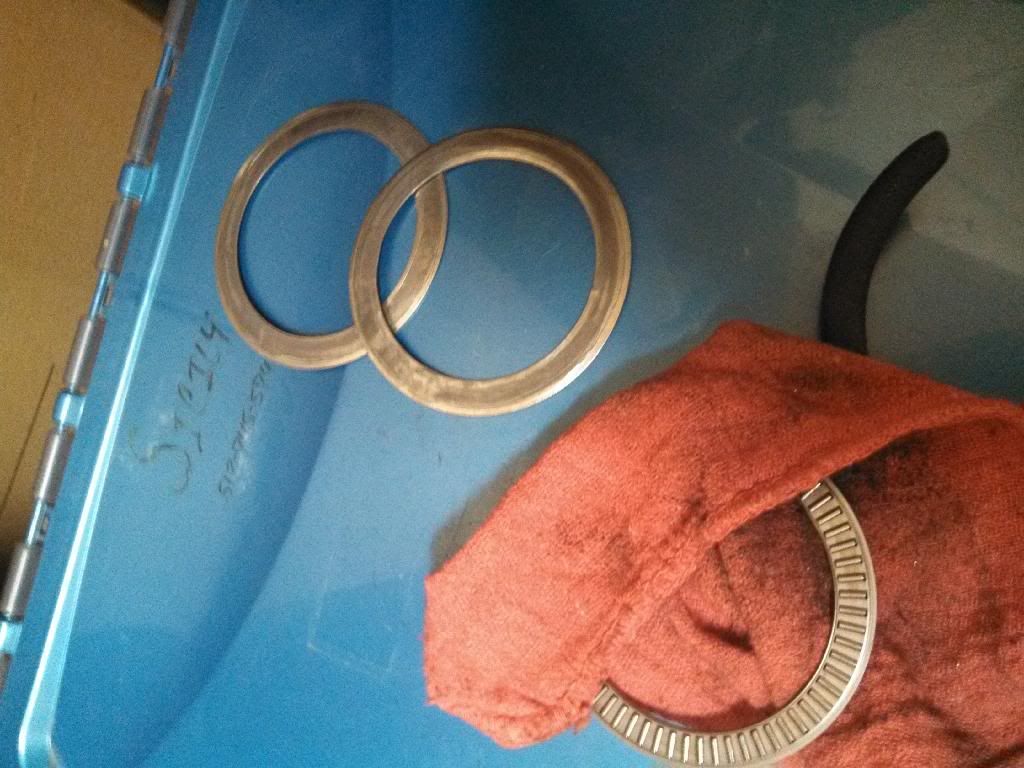

Bearings (1): http://www.summitracing.com/parts/ha...-109/overview/ They come as a kit. So one order is enough to do both of the fronts. That's all you need. Lube these up pretty good. I used white lithium grease. Haven't had any problems with it. You need these bearings on the front to help keep the steering from binding up. You can run them on the back if you want it to be easier to turn the adjuster nut, but I haven't worried about it.

Bushings(1): http://www.summitracing.com/parts/ens-9-8106r/overview/ These bushings will be needed for going under and over the mounts to avoid metal on metal contact with the strut rod. The hole is a tad bit too small at .375". I used a drill bit and a pair of vise grips to hold the bushings and enlarge the hole till it fit on the strut rod. The box comes with 8 but you only need 4. So if you screw one up you've got extras which is good news.

More Bushings (1): http://www.summitracing.com/parts/ens-3-6110r/overview/ These are sold as a pair. You only need one for each front assembly. So one pair is enough. You need these to avoid metal on metal contact of the spring and mount. They'll need modified a little bit and i'll show how they need to be for this particular mount style. You'll also see why this mount style isn't the best, but works.

Aside from the items listed above you're also going to need your choice of struts. I used KYB GR2's/Excel G's. You'll need a few washers to fit over the smaller part of the strut rod. These are for the bushings. You will also need some grease for the bearings as said before. I also chose to run covers on the fronts to avoid getting dirt/sand etc in the bearings.

These are the covers I run: http://www.summitracing.com/parts/is...0652/overview/ I don't have any complaints other than they're too long. The 14" version might work a little better. Mine are the 16" version. Whichever length you get, be sure that the diamater is 3.5". The 5" diamater will be too big.

So now that you've got your parts, the fun starts. Modifying the struts. It's a bit nerve racking, especially if you use brand new struts like I did. But take your time, and it'll be okay. Don't be a dummy. Where so some safety glasses. Getting **** in your eyes hurts. Gloves wouldn't be a bad idea either.

I'll go over modifying the bushings first. In this pic you can see how they come in the package.

You'll need to cut off this piece here.

And you'll end up with something like this. This shows why this isn't the best mount setup. It leaves part of the metal exposed which allows contact between the mount and spring. I can't say i've had any problems with it though. You can also see the part that was cut off sitting on the bench.

And this just shows that the spring on the mount.

Okay so you've modified your bushings for the springs. Now do the the smaller bushings so that they'll fit over the strut rod. This pic shows where the bushings need to be. The fronts are the black and the rear are the silver. This is obviously after I modified them.

Some of you might have noticed the black struts are different. If you didn't...look now cause you might run into this. The one on the right had a cap over it, for the dust boot from what Cam has told me. The one on the left did not have this cap and had a collar instead.

Here's what they look like before modification.

Here's what I discovered from doing some research when I ran into this issue myself. This is copied and pasted out of my ride thread, me talking about the one with the dust boot.

" I got on goggle and typed in the model number hoping to find a pic of a silver GR2. I didn't look very hard but all I found was the black Excel G. But the pics I was looking at I noticed 3 things. The first is that the piece that I have is not on the pics I found. There was just simply a metal plate. The second thing I noticed is that all of these ones with the plate, were also painted flat black , opposed to my gloss black. The third thing I noticed is that they have a different sticker, in a different location. But I didn't think much assuming it was a generic pic for all their struts"

After typing that out I checked the other box out of curiousity and saw I had a slightly different designed strut. Basically all you need to know about this mixup is that: If you get a strut with the dust boot cap thing. You can simply wedge a screwdriver and carefully pry it off. If you get one that doesn't have the cap, and has the collar instead, you have to grind it down till the sleeve fits over it.

This just shows me popping the cap off.

So do whatever you need to do with your struts wether it be remove the cap or grind down the collar. Once you get that done

you need to remove the factory spring perches so your coilover sleeves will slide over the strut body.

You can use this method here:

http://www.grandprixforums.net/showthread.php?t=26559

I personally don't like doing it that way. It's time consuming, and even after cutting off all those little pieces you still have to grind down the weld.

What I did was use an angle grinder with a small disc. I don't know the size right off hand. But I cut the weld all the way around and pulled the perches off in one big piece. Much faster, much easier in my opinion. But the way shown in that link works fine. Do whatever you're comfortable with.

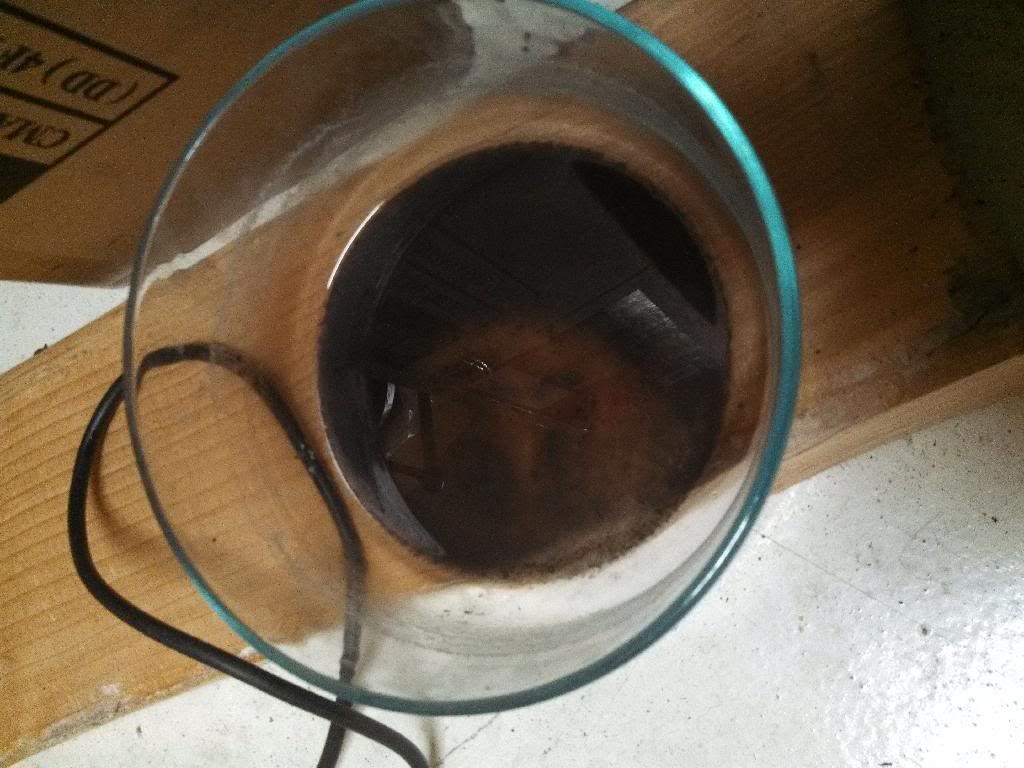

But first you need a way to mount it. Here's what I did. I took a 2X6 and slid it in where the spindle would normally be. Had to tap it in with a hammer. After that was on, I drilled a hole thorugh, and put a bolt/nut to secure the strut to the board. This holds the strut pretty well and keeps things from getting cray cray. Allows you turn the strut every which way you need in order to grind or whatever. In short, it works great. You can use this mount setup for all 4 struts which is also nice.

Here's a couple pix showing this little mounting setup.

Okay...so back to getting rid of the spring perches. Here's me doing it the way shown in that link, and all the little pieces.

Both of the rears I did that way. Then did the fronts the other way I said. I should've done all 4 the other way. MUCH easier and MUCH less time consuming. 100% recommend doing it this way.

Okay. Sooo. After you get your spring perches cut off you'll have something like this. This is a rear but you get the idea.

Test fit your sleeves and make sure they will slide all the way down. If the sleeves get caught up on the weld or whatever, take care of it. The only reason a front wouldn't slide down is if you have part of the weld left. The 2.17" sleeve is MORE than big enough to fit over a GR2. Once again this is a rear but you get the idea.

After you get the perches and welds taken care of you need to paint them to keep them from rusting. I used black on all of them. No real reason. It's what I had laying around. I used an enamel since that tends to be tougher. But here's a pic of them all painted up. You can also see the washers in this pic. The mount goes inbetween the bushings.

So you've got everything all good and modified. Your sleeves fit. Great. Time to assemble.

Start with your sleeve and adjuster nut. I'd wind it down about half way to start with. That's around stock height..probably a little lower.

Put your bearing on the adjuster nut, being sure to lube it up first.

Now slide a couple of washers over the strut rod and then a bushing.

Put your spring on the bearing. Your spring isoaltor/bushing should already be on the mount. Go ahead and put that on. The strut rod should come up through the mount.

Put a bushing and a couple more washers on the top side.

Finally put on the nut. I ran mine down pretty good. Probably more than needed. You should now have something like this.

Now. What I didn't show you was a bump stop since I don't have any yet. I'm going to try something like this for a bumpstop. Not necessarily that particular one but something like it. Also without the washers and bolt/nut of course.

http://www.oreillyauto.com/site/c/de...2267&ppt=C0367

Rears. The rears don't need a custom mount. We'll be using a regular mount. You can buy new ones or reuse your old ones, doesn't matter. If you're old ones are crappy, get some new ones.

Sleeves. When I ordered sleeves I ordered a 6.5"X2.1". These here: http://shop.a1racing.com/cok12457-tk.aspx. Don't do that. You don't need a sleeve that long. My car is fairly low and I have close to 2.5" of thread left underneath. That leaves plenty on the other side. The length isn't much of a problem. The problem with these is the ID is too small. They're raised on the inside and do NOT fit over the strut body. Do NOT fit. Do NOT buy them. One more time. DO NOT BUY THEM. Don't ****in do it. You'll thank me later, unless you want your car to be stock height or higher after the coilover install, cause even then your adjuster nuts will still be a good way down the 6.5" sleeve and you're going to have to do some work to make them fit. I'll post these couple pics to show why you don't want them that way you can understand what i'm talking about.

This is the raised part on the inside that doesn't fit over the strut.

Since I wasn't aware of this I bought these stupid sleeves...and this happened. Picked up a cylinder hone from Harbor Freight and had to hone out these sleeves which took FOR-EV-ER. (That's my buddy Rus honing out the sleeves)

So instead of going through the hassle, buy these sleeves instead, the same ones we used on the front.

Remember we're using a stock mount. So you're going to need a top hat for the rear.

These are the mounts I went with.

Right side (1): http://www.amazon.com/gp/product/B00...?ie=UTF8&psc=1

Left side (1): http://www.amazon.com/gp/product/B00...?ie=UTF8&psc=1

Top Hats (2): http://shop.a1racing.com/cok12470.aspx

Sleeves (2): http://shop.a1racing.com/cok12452-h.aspx

Adjuster Nuts (2): http://shop.a1racing.com/cok12460.aspx

Springs (2): http://www.summitracing.com/parts/hal-12-350/overview/

That's it for parts other than the struts and sway bar link setup. I'll get into that in a bit. I used GR2's here again. Currently i'm not running a rear sway bar since I don't care for cutting up the stock links and shortening them. I'm trying to find a link off a different car that's appropriate in length. Another option is heim joints but that will run you close to a hundred bucks, which is more than i'm willing to spend for a sway bar link setup.

Ok. So. We're going to say you already have the spring perches and sway bar link brackets cutoff. You've already got them painted up etc. We're going to say you're ready for assembly.

Start off the same way you do with the fronts, putting the sleeves and adjuster nuts on the body.

Then put the spring on, and the top hat on top of that.

Put your mount on and the strut rod should come up through once again. There will be a little sleeve that slides down inside the mount if you have a Monroe mount like I linked up there.

Then just put the washer on that's supplied with the mount.

Tighten down the nut and you're good.

Here's what you should have.

For the sway bar. Every setup i've seen is simply a piece of angle iron attached where the strut does, and then a hole drilled in it for a sway bar link to bolt onto. Easy and simple. These following three pics are from R.S. Hutchinson on ClubGP.

I plan on running something like that but finding a link I don't have to cut up.

That covers most of the stuff you'll need to know about making some coilovers. I'll go back later and add in how to put them on the car if someone would like.

Enjoy the read. Hopefully it helps someone out. If I mispelled some stuff or missed some punctuation here and there...get over it.