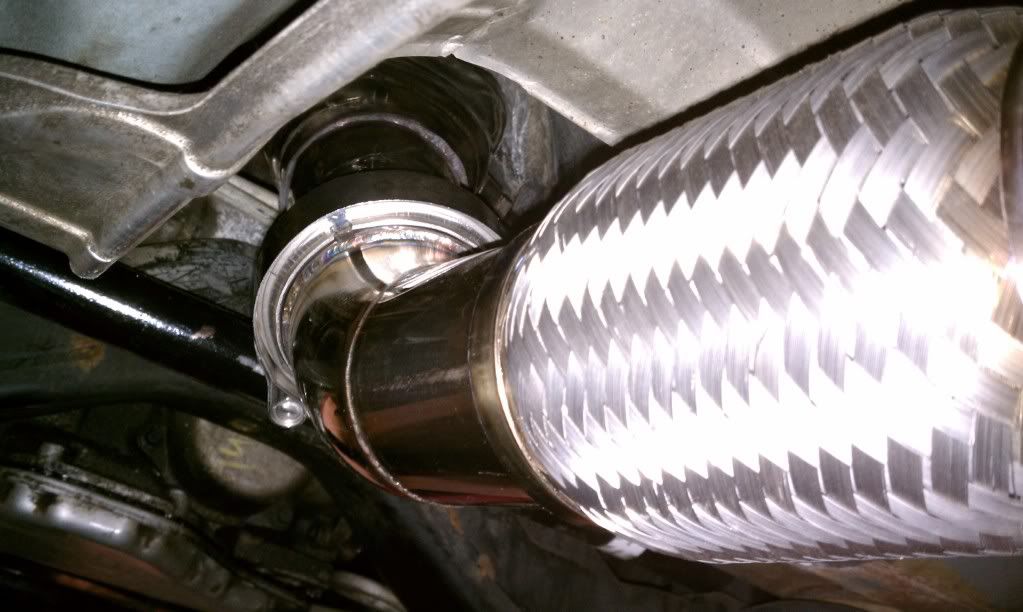

Pictures of them installed. Sounds like the v-band is ticking though, hope to fix the leak this week.

|

|

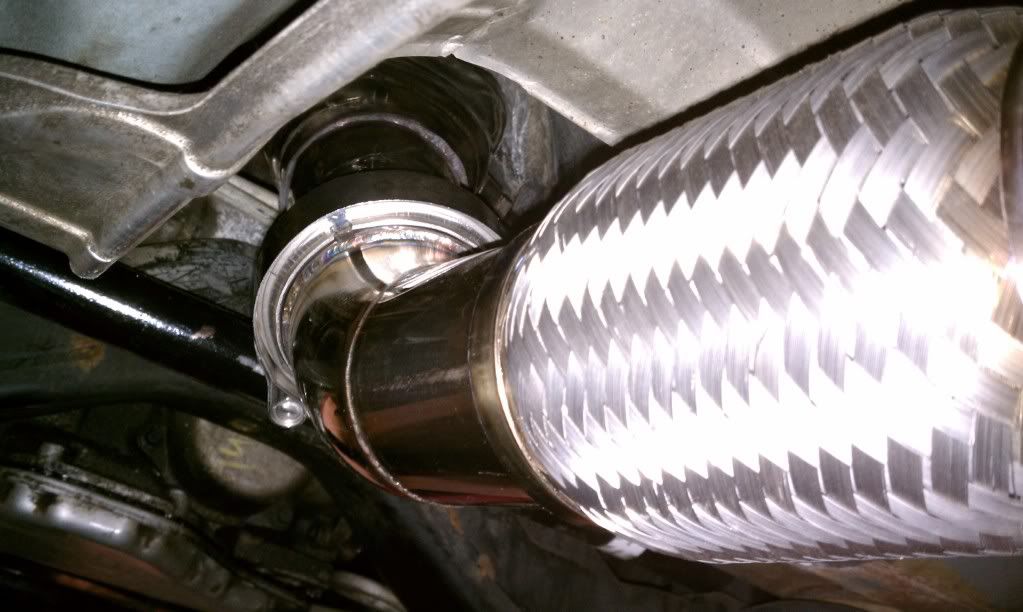

Pictures of them installed. Sounds like the v-band is ticking though, hope to fix the leak this week.

Those are already turned upward. They are not the lowest point anymore

I would put normal saddle clamps on there, band clamps like to pull apart.

Good to hear your install went ok. I wouldn't worry about the clamps. Torque them down to 50 ft lbs and they won't go anywhere.

I've actually seen better results with these clamps than any other types. Looks great Max. FWIW I'll be cleaning that pile of crap on the side of the garage now that I saw how bad it looks in the pics.

Happen to have any pics of the er uh.. adjusted firewall/tunnel area? I did that again Saturday and it works amazing.

So any update on a blue prints for the jig?

Amazing welds! Took me a while to figure out just what you did. That is one tight fitting set of headers! I don't understand why SD couldn't have done that in the first place.

Question:

what size pipe is the dp to that flex to your cat?

I just need to know if im gonna get speed daddy headers cause il prob get a high flow cat too.

the sd's come with a single walled flex pipe that over time will blow out and cause the tick sounds.

I replaced it with a double walled 3in ZZP flex pipe to never have the issue.

Tho, some people say they never have an issue with just throwing the SD's in just the way they are, but I didnt want to chance that.

so the 3 inch will bolt/weld up perfect with the SDs? just order it and install it with the headers?

Plus could anyone answer the question above? ^

would u say 3" exhaust or 2.5" for 3.8L S/C ?

I will def have a glasspack/resonator,

but 3", the car would be loud as hell wouldnt it...?

3in will line up/weld up perfect.

Just stick with your stock cat-back and either swap the res for glasspack or just leave it.

In my personal opinion I wouldnt change the mufflers either unless you do borla, because flowmasters and maganflow exhaust will drone.

The reason I stay keep you stock cat-back size is because it flows perfectly fine up to around 350 WHP which is a crap load and I doubt you will ever reach that point.

the previous owner put flowmasters on it -_-.

and borla is stupidly expensive and i can find borla pros on ebay but for the deecent price they only ship within USA. Im in canada.... f***.

so thats why i was thinking magnaflow.

Plus right now i have no resonator LOL so yeah flowmasters and no res.

sounds greatLOL.

thats why i wanna do exhaust and put in the longest glasspack i can, which magnaflow is 18" (body) and overall is 22" for the 3" glasspack.

Note: around $350 for 2 borla mufflers plus shipping.

:P

so quite pricey. and i need piping still with that at a shop when i get it installed.

How long would you say it would take a shop to install the headers?

Last edited by GrandPrixGTP1; 09-14-2011 at 10:24 PM. Reason: Added last question.

Max did you ever do the diagram for jig so we can make are own?

04 Impala SS Indy:

04 Impala SS Indy:

I made the jig that Max used. It was easy to make. Assemble the rear header and downpipe. Lay it on a strip of plywood and measure the angles at both ends. Cut a block of wood for each end that matches the angles. Lag the blocks onto each end of the pipe. Screw through the plywood into the blocks to hold it down. I used half inch plywood so a scrap strip of wood was attached to make it more rigid. Measure the angles under the pipes and cut pieces of wood that match. This will be your guide for where the floor of the car will be. Attach them to the jig. With both ends of the pipe attached, you can now cut the middle out and piece back together the way you want it. Tack weld it together then remove from the jig and finish welding.

| « Previous Thread | Next Thread » |

| Tags for this Thread |