Oh yeah. the old piston pin bores were oblong. You could wiggle the pin side to side a bunch. The bores on the new pistons are a nice slip fit.

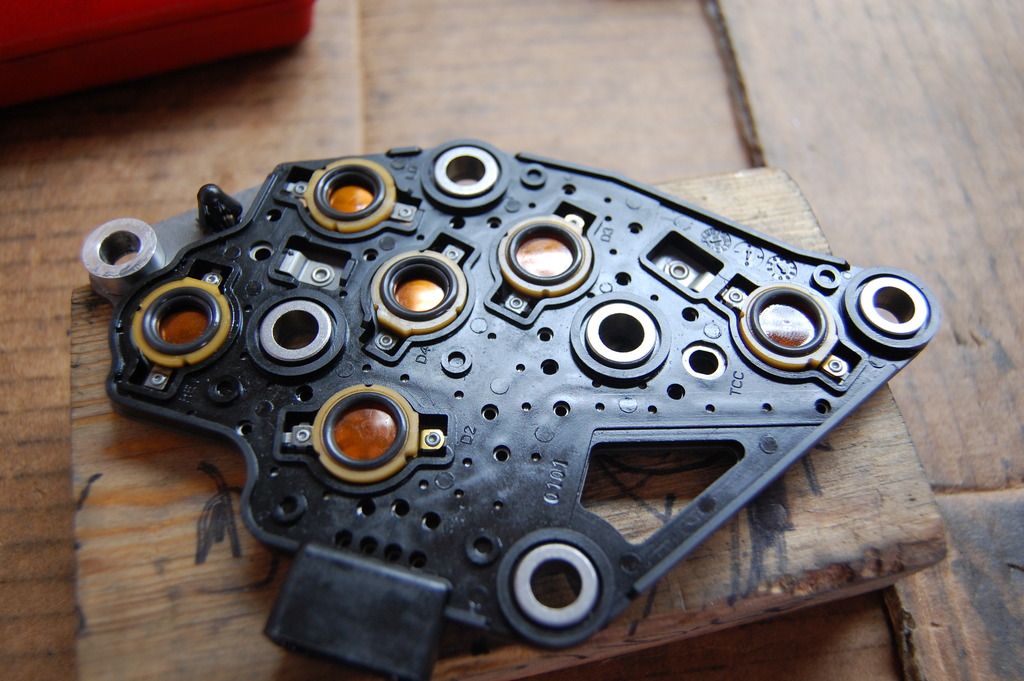

New o-rings on the MPS and checked function of all the switches. All check good.

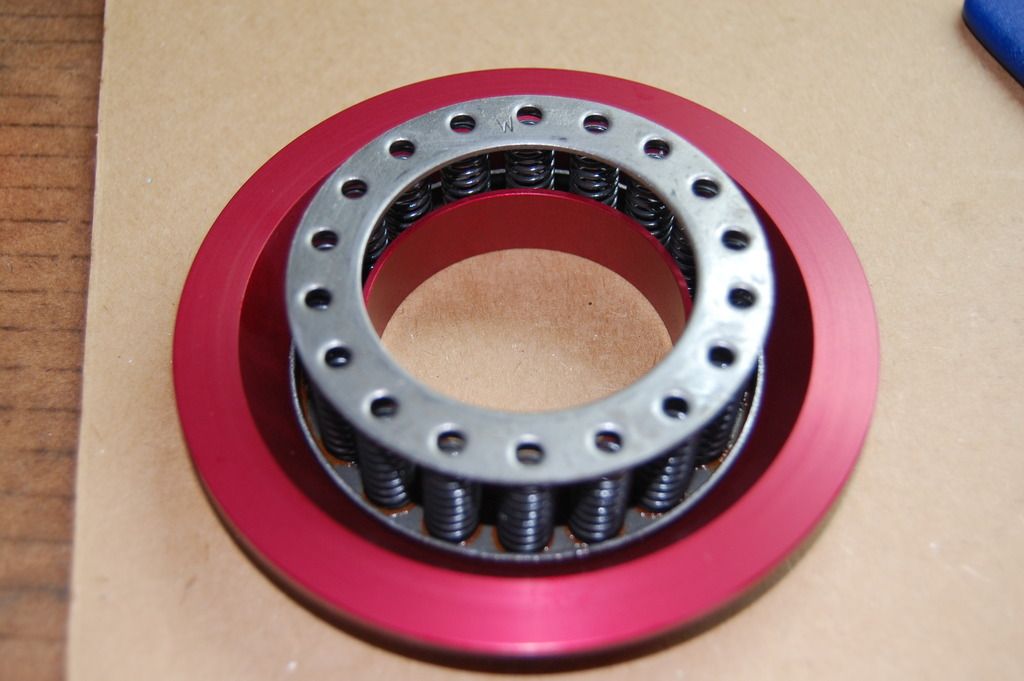

I finally got to build the input/3rd clutch packs. Couldn't do anything till I got this. It came today. The Sonnax 3rd clutch piston kit. PN 84965-01K

Pictures of the assembly progress

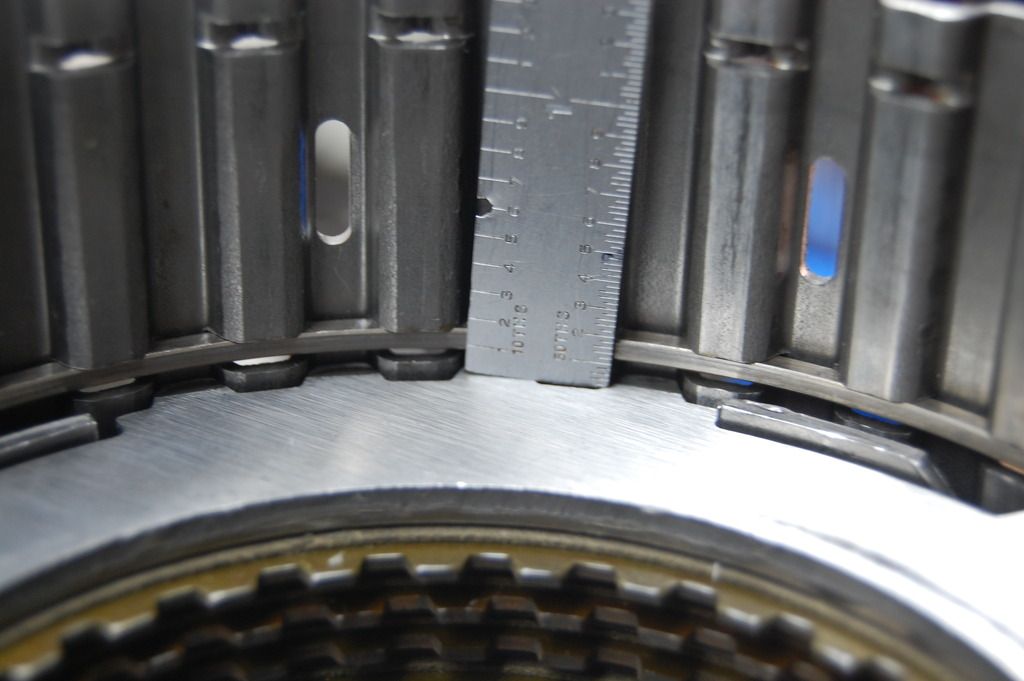

Once that was in, I could check the clearance on the 3rd with the standard kit components. I stopped checking after 0.085" went in.

I knew if I was over 0.085" a shaved outer splined 3rd clutch would get me pretty close. The steel part measures just under 0.050"

Here it is de-clutched

That put me right where I want to be. Picture shows a 0.035" feeler, but it's actually closer to 0.040"

On to the input clutch pack. It's loose

My solution was to replace one of the 0.050" steels (used in the 10pc stack) with a 0.078" steel (used in the 8pc stack). This put me around 0.045" and that was close enough. Another thick plate would have made it too tight. From what I've read, the clearance on the input clutch assembly is less critical. It's not a "shifting" clutch.

Now that all clearances have been checked, the clutches can soak.