BrandonHall10

Solving problems

Edit:

Now that it's complete, here's the full build sheet:

Master rebuild kit

-New BW frictions, Raybestos steels, seals, gaskets, and filter

PNH JTFM Torque convertor (Stock repalcement)

Bonded separator plate

Torlon check balls

Oversize 2nd steel plates x2

Molded 2nd apply piston

Sonnax 3rd clutch piston kit (984965-01k)

TEP reconditioned reaction carrier

TEP reconditioned input piston

300m iput shaft

7/8" 2.93 ratio sprockets

Borg warner PCS

Borg warner TCCS

Shift solenoid x2

Superior AFL valve repair kit

Superior valve body kit

Sonnax TCC relief valve

Sonnax lube tube clamp

Trans-go shift kit

Hardened 4th clutch hub

ZZP aluminum pan (With improved steel threads)

New 2-1 coast band

New 7/8" Hy-Vo chain

New 1-2 Sonnax shift valve

New accumulator pistons

New bushings (All of them)

New thrust washers

New Lube dam

New magnets

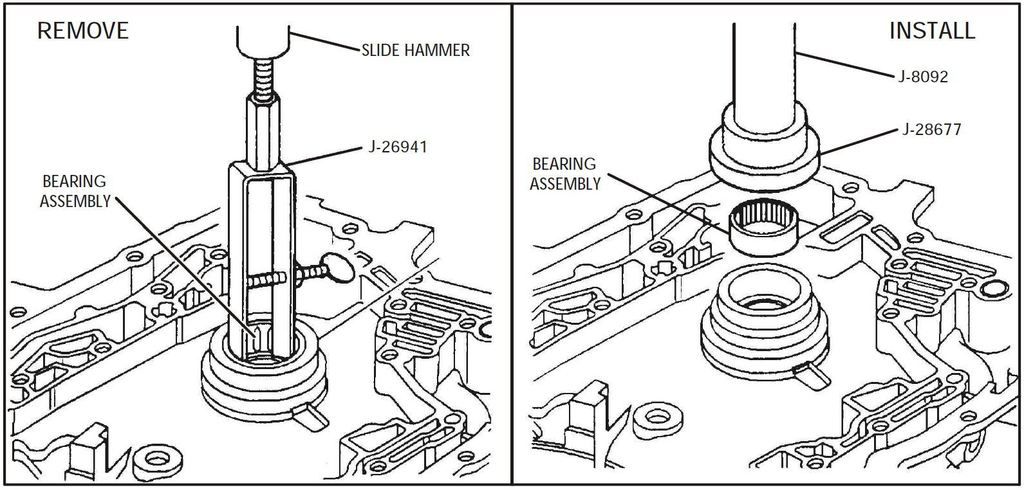

New drive sprocket bearing

"Mods" Include:

Modified shift kit spring arrangement

Enlarged separator plate feed holes

Tightened 2nd clutch pack

Tightened 3rd clutch pack

5 Friction input clutch

See post #232 for it's real world review.

:th_divider::th_divider::th_divider:

Begin original post:

This fall/winter, I'm planning on building a transmission for my car.

Here's what I'm planning on using for parts:

PNH Torque convertor

Master rebuild kit

-New frictions, steels, seals, gaskets, and filter

All bands

Bonded spacer plate

Torlon check balls

Oversize 2nd steel plates x2

Molded 2nd apply piston

Molded 3rd apply piston

TEP reconditioned reaction carrier - Original is out of spec

300m iput shaft

7/8" 2.93 single chain set

Borg warner PCS

Borg warner TCCS

AC Delco shift solenoid x2

Superior AFL valve repair kit

Superior valve body kit

Sonnax TCC relief valve

Trans-go shift kit

Dorman pan w/ drain plug - Junkyard poked the original

Hardened 4th clutch hub

Differential lube tube clamp

Lube dam

Round magnet

Here's the "mods" I plan to do:

Tightened 2nd clutch pack

Tightened 3rd clutch pack

Convert to internal cooler check ball

Here's what I'm debating:

Bushings - Not seeing any substantial wear on the originals

Drive sprocket bearing - Feels tight, but I'm told it's a common failure (?)

Bonded sonnax 3rd apply piston - Because I'm right there

The core transmission was pulled from a smashed junkyard '02 Regal with an unknown history. The only thing I know for sure is, 4th gear was gone (based on the completely absent splines on the 4th hub). No chunks in the pan, average amount of sludge on the magnet. Fluid looked.... average for a Tucson w-body. No burned or scarred internals.

This setup is probably overkill for my current, or even future mods, but here's my though process: I'm going to pull and shelf my current stock, working transmission. Install the built trans and roll on that until I eventually move on from this car. At that point, I'll re-install the stock trans and sell the built trans as a low mile working unit. Hopefully for what I have into it.

For what it's worth, I have all the time in the world to do this build. No rush on anything. I also have HP tuners, so I can make adjustments in the PCM to take advantage of all the improvements in this build.

So what do you guys think? Is it a solid plan? What are your thoughts on the pieces I'm debating?

Now that it's complete, here's the full build sheet:

Master rebuild kit

-New BW frictions, Raybestos steels, seals, gaskets, and filter

PNH JTFM Torque convertor (Stock repalcement)

Bonded separator plate

Torlon check balls

Oversize 2nd steel plates x2

Molded 2nd apply piston

Sonnax 3rd clutch piston kit (984965-01k)

TEP reconditioned reaction carrier

TEP reconditioned input piston

300m iput shaft

7/8" 2.93 ratio sprockets

Borg warner PCS

Borg warner TCCS

Shift solenoid x2

Superior AFL valve repair kit

Superior valve body kit

Sonnax TCC relief valve

Sonnax lube tube clamp

Trans-go shift kit

Hardened 4th clutch hub

ZZP aluminum pan (With improved steel threads)

New 2-1 coast band

New 7/8" Hy-Vo chain

New 1-2 Sonnax shift valve

New accumulator pistons

New bushings (All of them)

New thrust washers

New Lube dam

New magnets

New drive sprocket bearing

"Mods" Include:

Modified shift kit spring arrangement

Enlarged separator plate feed holes

Tightened 2nd clutch pack

Tightened 3rd clutch pack

5 Friction input clutch

See post #232 for it's real world review.

:th_divider::th_divider::th_divider:

Begin original post:

This fall/winter, I'm planning on building a transmission for my car.

Here's what I'm planning on using for parts:

PNH Torque convertor

Master rebuild kit

-New frictions, steels, seals, gaskets, and filter

All bands

Bonded spacer plate

Torlon check balls

Oversize 2nd steel plates x2

Molded 2nd apply piston

Molded 3rd apply piston

TEP reconditioned reaction carrier - Original is out of spec

300m iput shaft

7/8" 2.93 single chain set

Borg warner PCS

Borg warner TCCS

AC Delco shift solenoid x2

Superior AFL valve repair kit

Superior valve body kit

Sonnax TCC relief valve

Trans-go shift kit

Dorman pan w/ drain plug - Junkyard poked the original

Hardened 4th clutch hub

Differential lube tube clamp

Lube dam

Round magnet

Here's the "mods" I plan to do:

Tightened 2nd clutch pack

Tightened 3rd clutch pack

Convert to internal cooler check ball

Here's what I'm debating:

Bushings - Not seeing any substantial wear on the originals

Drive sprocket bearing - Feels tight, but I'm told it's a common failure (?)

Bonded sonnax 3rd apply piston - Because I'm right there

The core transmission was pulled from a smashed junkyard '02 Regal with an unknown history. The only thing I know for sure is, 4th gear was gone (based on the completely absent splines on the 4th hub). No chunks in the pan, average amount of sludge on the magnet. Fluid looked.... average for a Tucson w-body. No burned or scarred internals.

This setup is probably overkill for my current, or even future mods, but here's my though process: I'm going to pull and shelf my current stock, working transmission. Install the built trans and roll on that until I eventually move on from this car. At that point, I'll re-install the stock trans and sell the built trans as a low mile working unit. Hopefully for what I have into it.

For what it's worth, I have all the time in the world to do this build. No rush on anything. I also have HP tuners, so I can make adjustments in the PCM to take advantage of all the improvements in this build.

So what do you guys think? Is it a solid plan? What are your thoughts on the pieces I'm debating?

Last edited: